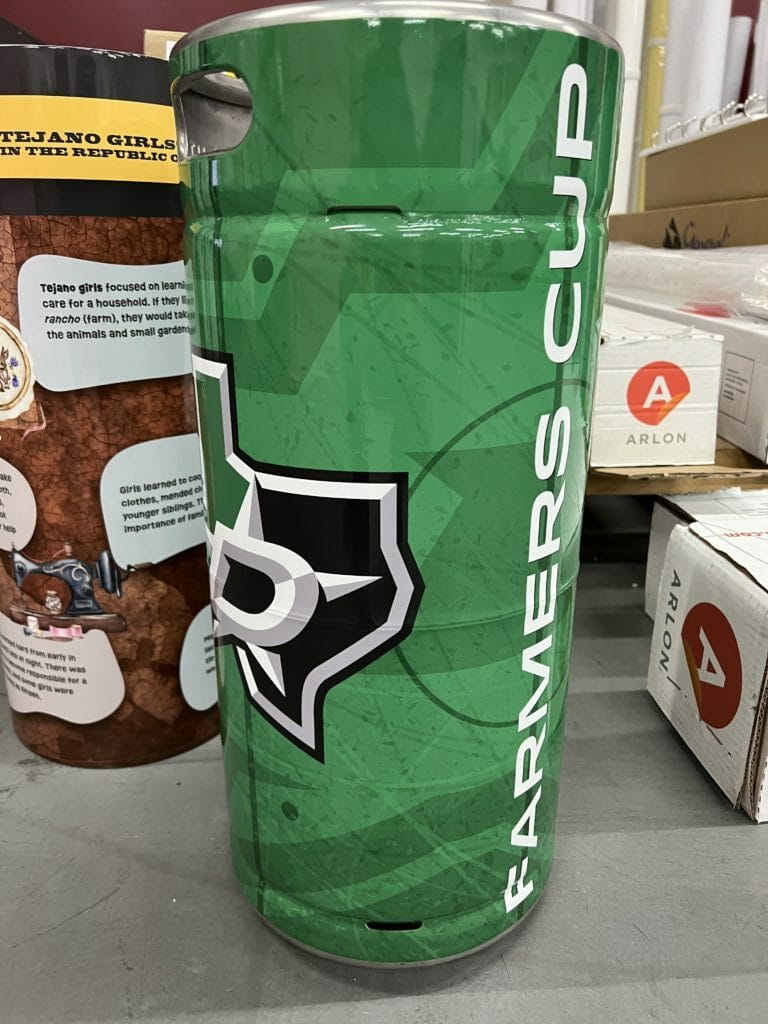

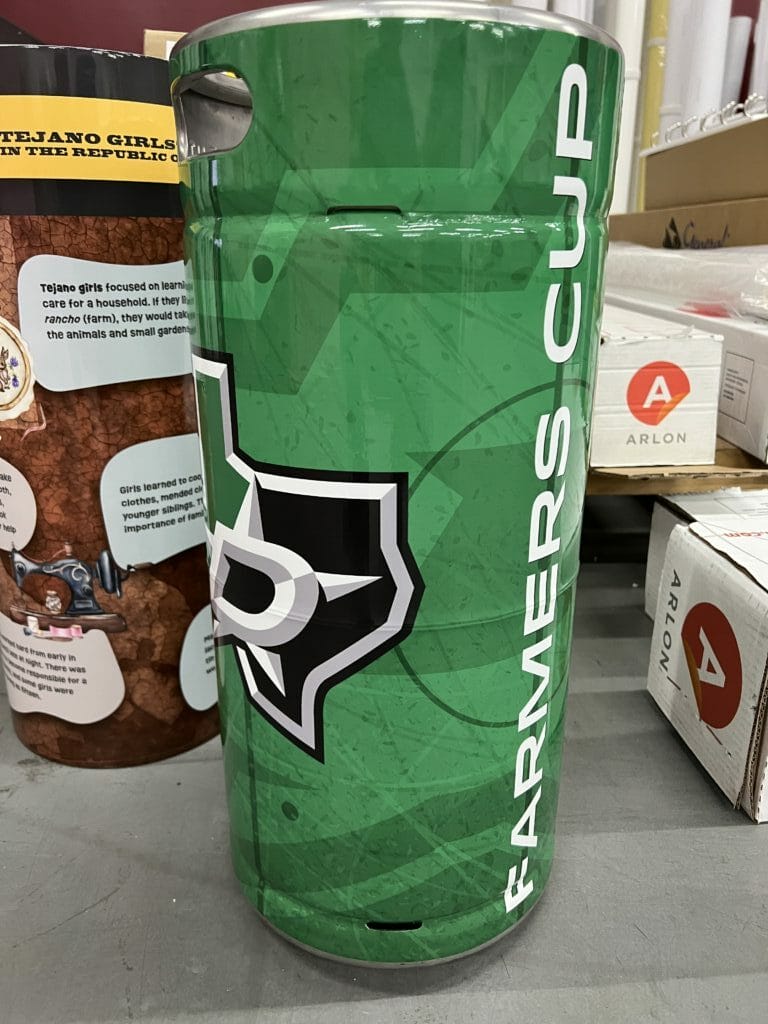

pecialty printed vinyl wrapping is a popular technique used to customize and decorate various items, including kegs, benches, cars, buses, zambonis, golf carts and more. Vinyl wrapping allows you to add unique designs, patterns, or branding to a keg, making it visually appealing and eye-catching. Here’s a step-by-step guide on how to specialty print vinyl wrap a keg:

- Design: Start by creating a design or artwork that you want to apply to the keg. You can use graphic design software like Adobe Photoshop or Illustrator to design the artwork or hire a professional graphic designer if needed.

- Measurements: Measure the dimensions of the keg, including its circumference and height. Use these measurements to create a template for the vinyl wrap. Ensure that the template matches the keg’s size accurately.

- Printing: Once you have the design and template ready, you need to find a specialized printing service that offers custom vinyl printing such as Positive Marketing. Provide us with your design and template specifications, and they will print the artwork onto a vinyl sheet.

- Cleaning the keg: Before applying the vinyl wrap, make sure the keg is clean and free of any dirt or oil. Use a mild detergent and water solution to clean the surface thoroughly. Dry it completely before proceeding.

- Applying the vinyl wrap: Carefully peel off the backing from the vinyl wrap and align it with the template on the keg. Start from one end and gradually press the vinyl onto the keg’s surface, smoothing out any bubbles or wrinkles as you go. You can use a squeegee or a similar tool to ensure proper adhesion.

- Trimming: Once the vinyl is applied, use a sharp knife or cutting tool to trim off any excess vinyl. Take your time and make precise cuts to achieve clean edges.

- Finishing touches: After trimming, go over the vinyl wrap again to ensure it is properly adhered and there are no air bubbles or loose edges. Smooth out any imperfections with the squeegee or your hands.

- Sealing (optional): To provide additional protection and durability, you can consider applying a clear vinyl laminate or a protective sealant over the printed vinyl wrap. This step is optional but can help prevent the design from fading or peeling off over time.

Keep in mind that specialty vinyl wrapping requires skill and precision. If you’re not confident in doing it yourself, you may want to hire a professional vinyl wrap installer like ourselves who has experience with custom designs on kegs or other similar objects.